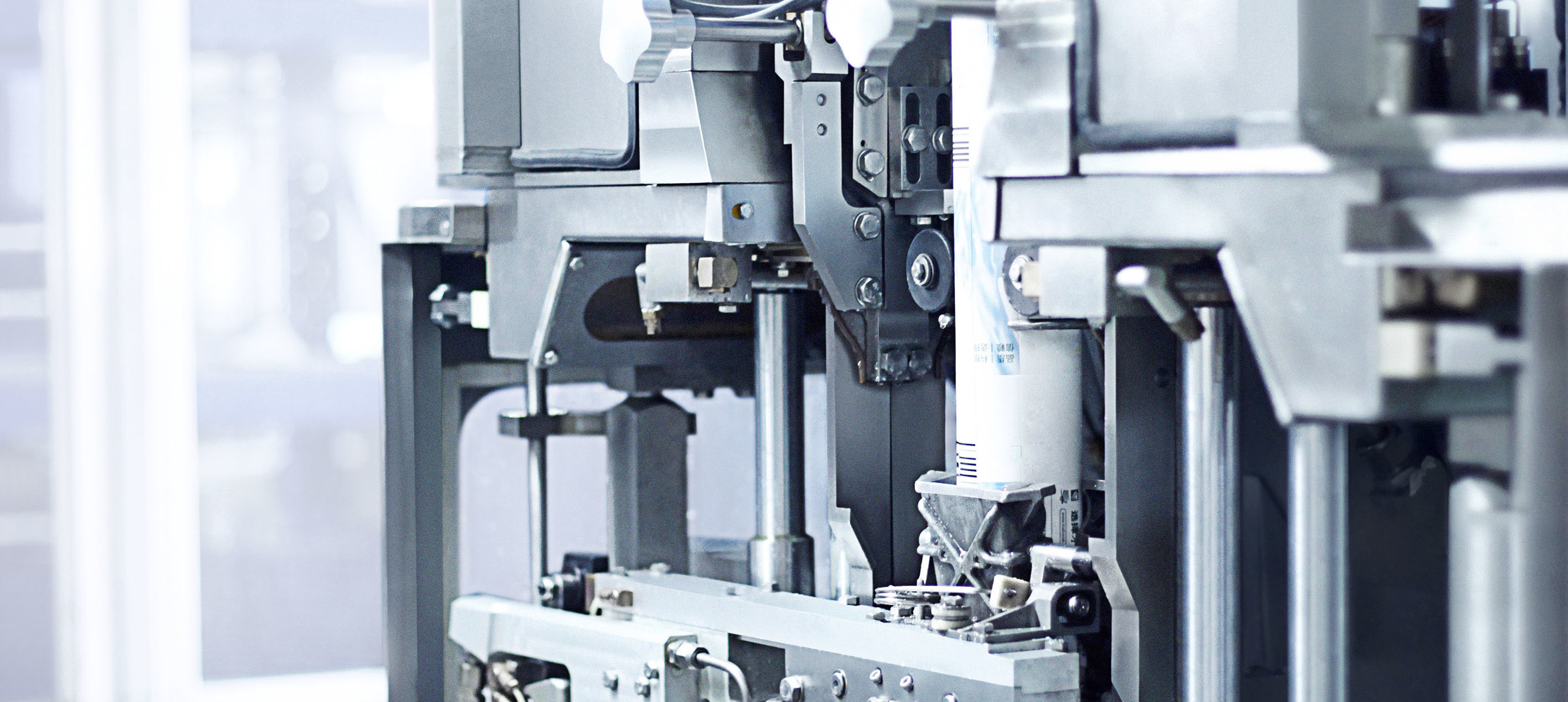

Natural interface detection and packaging system that is popular among customers

The customer said that the Fenmei Natural Interface Inspection and Disposal System solves the various problems that the pillow packing filling machine needs to rely on manual inspection of natural connectors of packaging materials. The Fenmei Natural Interface Inspection and Disposal System adopts ultrasonic detection method, which can automatically eliminate the joints according to changes in the thickness of the packaging material. Compared with previous manual testing, it effectively improves work efficiency, reduces labor load, and eliminates the potential for joint flow into the market caused by manual negligence. This natural interface detection and packaging system has been adopted by many well-known dairy brands.

No need to purchase the entire set, Fenmei valve sealing kit effectively saves customers costs

For valve sealing kits that are prone to wear, customers cannot purchase them separately, so they can only replace the entire set of valves, which is expensive. To this end, Fenmei has conducted surveying and mapping and research and development of valve sealing kits, and the product needs to pass actual machine testing to ensure that the performance and life cycle can meet customer needs. The launch of Fenmei valve sealing kit products solves the problem that valves can only be replaced in the entire set, and the customer has reduced the maintenance cost by about 80%.

Fenmei homogenizer plunger extends service life to 2500 hours

The plunger of homogenizer has a short service life, and when producing certain specific products, the service life is as low as hundreds of hours. In order to improve the usability rate of equipment and reduce customer production costs, Fenmei has successfully developed a plunger with a maximum service time of about 2,500 hours, divided into 40mm and 45mm specifications, both of which have been verified by food contact materials. The Fenmei homogenizer plunger, which can reduce maintenance costs by about 75%, is favored by many well-known dairy brands and has good feedback on use.

Fight two birds with one stone, Fenmei helps customers repair pillow charter filling tube

The filling tube latch slot on the upper part of the pillow charter machine is prone to wear, resulting in poor firmness of the upper and lower filling tube connections. In production, there will be a risk of falling of filler tubes. Fenmi’s solution is to first repair and reuse the upper and lower infusion tubes of the pillow charter flight to save the cost of purchasing new products. Secondly, the sealing effect and firmness are enhanced by improving the end of the filling tube into a double sealing ring. The modification fee is only 15% of the repurchase price, and the customer's interests are protected.

Customer feedback: Fonmei Quick Pack Cleaning Cup, easy to operate and worry-free

The original cleaning cups of each capacity of brick-pack filling machine are prone to leakage of acid and alkali liquid during loading and unloading, resulting in corrosion of the jaws. The Fenmei Express Cleaning Cup is simple to operate, can be disassembled and installed quickly, and has the characteristics of double sealing, which can play a good protective role for the jaws, so customers no longer need to worry about jaw corrosion. The Fenmei Express Cleaning Cup has successfully obtained the utility model patent license, patent number 201720082279.1.